Gas leak detector from MSR-Electronic serves as a bus system in buildings, garages and industrial settings.

Bus systems are the core of building automation and connect different devices to each other. The components integrated into the devices use the communication channels between the devices to exchange sensor signals. A gas leak detector is also ideal as a bus system.

Information is transmitted according to uniform rules which ensure that all components can respond and work uniformly. They are notably installed in new buildings for their energy and resource efficiency.

What is a bus system?

A bus system is a system that connects different components for the purpose of data transmission. The system monitors and combines the functions of the devices, such as an alarm system. Consumers, sensors and switches are connected to each other by means of a low-voltage cable.

©MSR-Traffic GmbH

©MSR-Traffic GmbH

Because all of the components connected to a bus system can send and receive data, the individual components cannot send and receive data simultaneously, as this can cause unwanted collisions.

For this reason, the components should only be ready to receive if they are relevant to the current data.

The bus system is managed either directly via the processor or via its own bus controller. The components are assigned set times at which they can communicate.

What is the difference?

Analogue signal (4-20 mA/2-10 V) vs digital bus signal: While an analogue signal with complex cable infrastructures is associated with additional costs, more difficulty in troubleshooting due to insufficient diagnostic information and higher vulnerability to failures and processing inaccuracies, a digital bus signal represents the better choice with many technical advantages.

Why a bus signal?

- Additional functionality

- Cost efficiency for large-scale plants

- Less wiring effort

- Less space required in the switch cabinet

- More secure against unwanted white noise

- Information and data are written and read remotely

- Maintenance intervals

- Fault notifications

- Faster troubleshooting due to the diagnostic information available

- Higher protection against third-party interference

Bus system – MSR-Electronic’s approach

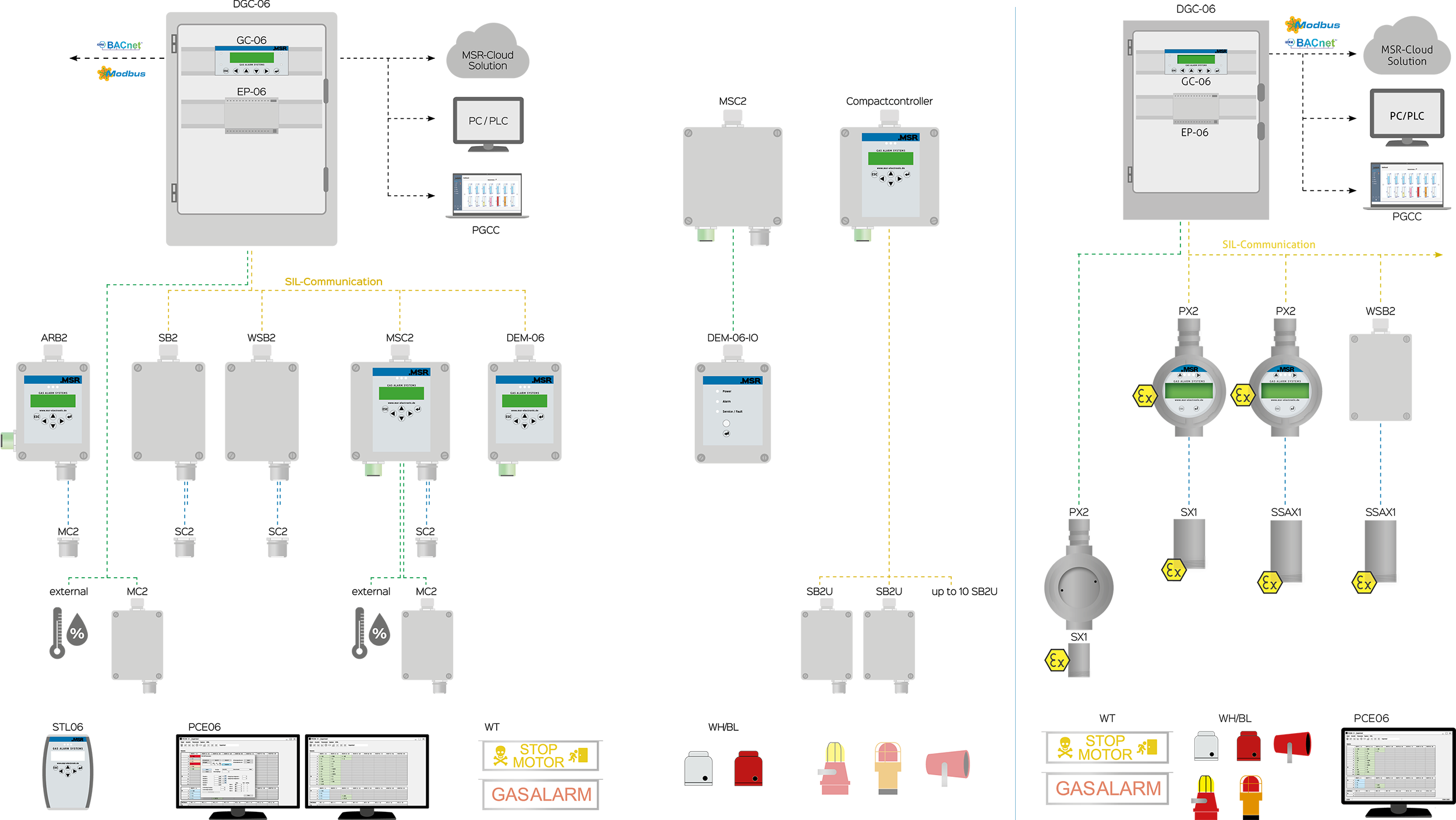

The gas leak detectors in the product series PolyGard®and PolyXeta® from MSR-Electronic are used as bus systems in a number of projects in the industrial sector, such as in the oil and gas industry and petrochemicals, as well as in buildings, garages and laboratories.

Producing interfaces for various building management systems via Modbus RTU, Modbus TCP/IP or BacNet makes it possible for individual bus users to query measuring values, maintenance intervals and fault notifications remotely.

©MSR-Traffic GmbH

©MSR-Traffic GmbH

MSR-Electronic’s approach to a solution

The SC2 gas sensor in the PolyGard® series is used as a bus system for buildings, garages and labs, and gas sensors SSAX1 and SX1 in the PolyXeta® series are used in the industrial sector.

The bus system for PolyGard® for buildings, garages and labs

©MSR-Traffic GmbH

©MSR-Traffic GmbH

The intelligent digital sensor head SC2 detects toxic, flammable gases, Freon gases and refrigerants.

In addition to the sensor element, the sensor contains an electronics system with an amplifier and a μcontroller for measurement value processing.

The μprocessor's internal memory stores all of the gas sensor’s relevant data and measuring values, fail-safe, and transmits it digitally to the board (e.g. SB2) via MSR’s own local bus. A device can be maintained by simply switching the gas sensor or by performing the integrated, convenient calibration routine on the plant itself.

The bus system for PolyXeta® in industrial ATEX areas

In addition to the sensor element and the amplifier, the SX1/SSAX1 digital sensor head contains a μcontroller for measurement value processing. This controller stores all of the gas sensor’s relevant data and measuring values in a fail-safe manner, and transmits it digitally to the gas leak detector PX2/ WSB2 board via the local bus.

©MSR-Traffic GmbH

©MSR-Traffic GmbH

The measuring value can be output as a PWM signal. Calibration management is also integrated into the sensor head’s μcontroller.

It is calibrated by simply switching the sensor head or by performing the integrated, convenient calibration routine on the plant itself.

BENEFITS of bus systems at MSR-Electronic

- Read all data remotely

- More convenient to replace

- Password-protected against third-party intrusion

- Lower price for bigger systems (many sensors and low number of necessary relays)

- Save space in the switch cabinet

- Relays can be activated in the field – less wiring effort

- Zone control

MSR-Electronic has long-standing client relationships, which are characterised by reliability and mutual trust. When you choose a bus system from MSR-Electronic, you benefit not only from the many technical advantages, but from quality, availability, competitive products, responsibility to clients and business partners and openness to individual requirements.

Further information on MSR products can be found in the current online catalogue or in the webshop www.msr-24.com.