Together with its certified partners, MSR-Electronic offers commissioning, installation and maintenance of fixed gas detection systems. As a manufacturer of gas detection devices, MSR operates an international network of partners to offer these services worldwide.

The offers for the services are prepared in close collaboration with the service providers and coordinated together with the customer. Thus, the customers receive a complete package with all requested services from one source.

The configuration

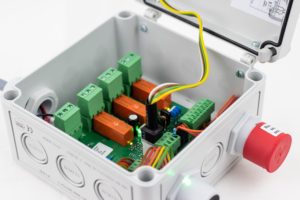

A crucial component when commissioning or maintaining the gas detection systems on site is the basic setting of the Gas-Controller . The Gas-Controller is the heart of the gas detection system. Here the individual measured values and requirements of the customer are stored.

©MSR-Electronic GmbH, Germany, MSC2-Multi-Sensor-Controller

During commissioning of the gas detection system, the bus devices must also be addressed, the warning thresholds must be set to valid standards and the triggering units must be checked.

Within a maintenance, after the maintenance interval has expired, the entire system first receives a visual inspection.

Then the preset configuration of the Gas-Controller is checked for up-to-dateness and the sensors are recalibrated during maintenance.

This ensures that correct values always reach the evaluation unit or the Gas-Controller.

The calibration

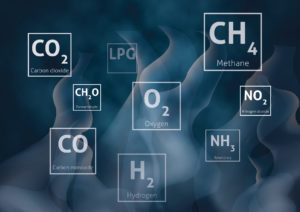

©MSR-Electronic GmbH, Germany, MSC2-Multi-Sensor-Controller

During calibration, the sensors are recalibrated because of their natural deviation after the specified interval.

During this calibration, the zero point is set first, i.e. the sensor is gassed in its natural ambient air or with zero gas and calibrated to this value.

The 2nd value to be calibrated should be between 30 % and 90 % of the sensor measuring range. This calibration is then performed with the gas to be measured.

For example, a carbon monoxide (CO) sensor with a measuring range of 300 ppm is calibrated with a test gas between 90 ppm and 275 ppm.

The maintenance of gas detection systems

Furthermore, it is essential to test triggering units such as warning signs, warning horns or flashing lights during maintenance of gas detection systems. The switching contacts, operating display and fault message are checked as well.

©MSR-Electronic, diagram gases

The functionality of an emergency power supply if available is also verified. Afterwards, the system receives a test sticker and the completion of the maintenance is noted in the inspection log. All inspection procedures as well as necessary, pending maintenance are documented in the maintenance log and the absence of defects is certified.

For an existing gas warning system, it is imperative to comply with the maintenance intervals. This helps to receive correct sensor values in the evaluation unit. It also guarantees that the system functions properly in the event of an increased gas concentration and that safety for people and systems is ensured.

Further information on MSR products can be found here in the current MSR-Electronic online catalog or in the webshop www.msr-24.com.