The MGC2 Multi-Gas-Controller from MSR-Electronic protects people from the irritant gas ozone

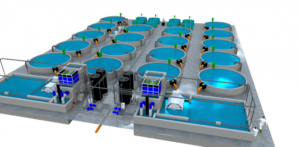

The unbeatable advantage of fish farming in a Recirculating Aquaculture System (RAS) lies in the fact that the production is independent of the location. No natural body of water is necessary. Production has minimal impact on the environment as it is a closed system. The plants can be built near consumer markets and also in regions where there is actually not enough water or no suitable climatic conditions for a selected fish species.

At the same time, high stocking densities can be realised due to the good water quality without losing sight of animal welfare. The amount of water required in a RAS is significantly less than in traditional aquaculture fish farming in natural waters, as water resources are recycled.

© REX M recirculation system-aquaculture-filtration

Water treatment and disinfection play an essential role in aquaculture. Farmed fish are sensitive to pathogens, water quality and toxic substances.

A highly effective treatment method for better water quality and disinfection of the facilities is ozone oxidation or ozonation. Besides eliminating pathogens, it is ideal for removing nitrite, colour, taste and odour.

A well-known producer of Atlantic salmon works with advanced RAS technology, not least to protect the environment while producing excellent salmon quality.

Gas sensors and controllers from MSR-Electronic are used for targeted ozone and oxygen gas monitoring. Ozone is a health risk and therefore dangerous for the employees working in the ozone production facilities.

MSR solutions for reliable ozone and oxygen gas monitoring

The Multi-Gas-Controller (MGC2) from MSR-Electronic monitors toxic and combustible gases, refrigerants and oxygen in conjunction with gas sensors. In the current application – RAS aquaculture – it is ozone and oxygen.

The MGC2 monitors the measured values and activates the alarm relays if the set alarm thresholds for pre-alarm and main alert are exceeded in case of gas leakage. Various output and input options allow for easy integration into existing systems. Up to 3 remote analog sensors can be connected to the MGC2. The MGC2 thus represents the compact variant for analog sensors.

Benefits

©MSR-Electronic Gas Measurement Multi-Gas Controller

- Internal function monitoring with integrated hardware watchdog

- Hardware and software according to SIL compliant development process

- Easy maintenance by replacing the sensor head or via comfortable on-site calibration

- Modular technology (plug-in and exchangeable)

- Reverse polarity protected, overload and short-circuit proof

- 3 analog inputs 4–20 mA for analog sensors

- 3 relays with change-over contacts, potential-free max. 240 V AC, 5 A

- 2 transistor outputs, 24 V DC, 0.1 A (plus switching)

- 2 digital inputs

- Serial RS-485 interface with protocol for DGC-06 or Modbus

- Different types of housing with IP65

Options

- Warning buzzer and status LED (WAO) for alarm, fault, operation and service

- Reset button, display, UPS

- Operating voltage 230 V AC with wide range input 100–240 V AC

The investment costs of RAS technology are high to operate a RAS successfully. By optimising all the relevant water parameters, however, RAS farms allow high stocking densities and feed rates and, thus, high growth rates and better utilisation of feed. That is why RAS productivity is exceptionally high compared to other fish farming systems.

Further information on MSR products can be found here in the current MSR-Electronic online catalog or in the webshop.