Necessary gas monitoring during fermentation with the DGC-06 from MSR-Electronic.

Research and development of new active ingredients and dosage forms are of central importance in the pharmaceutical industry. It is equally important for pharmaceutical production to obtain active ingredients from microorganisms or mammalian cells in large fermenters. The addition of bacteria, fungi or enzymes produces organic substances that are further processed in various steps such as grinding, granulating, coating and tableting.

The risks without gas monitoring.

Imagine a pharmaceutical plant releasing a toxic gas such as carbon dioxide (CO2 ) or a combustible gas such as methane (CH4 ) during a fermentation process. Without reliable gas monitoring, this gas could escape unnoticed into the environment, which could have catastrophic consequences. Employees would be at risk, production processes could be interrupted and the financial losses due to necessary repairs and downtime would be enormous. Recognising such dangers at an early stage is virtually impossible without adequate monitoring.

Solution from MSR-Electronic.

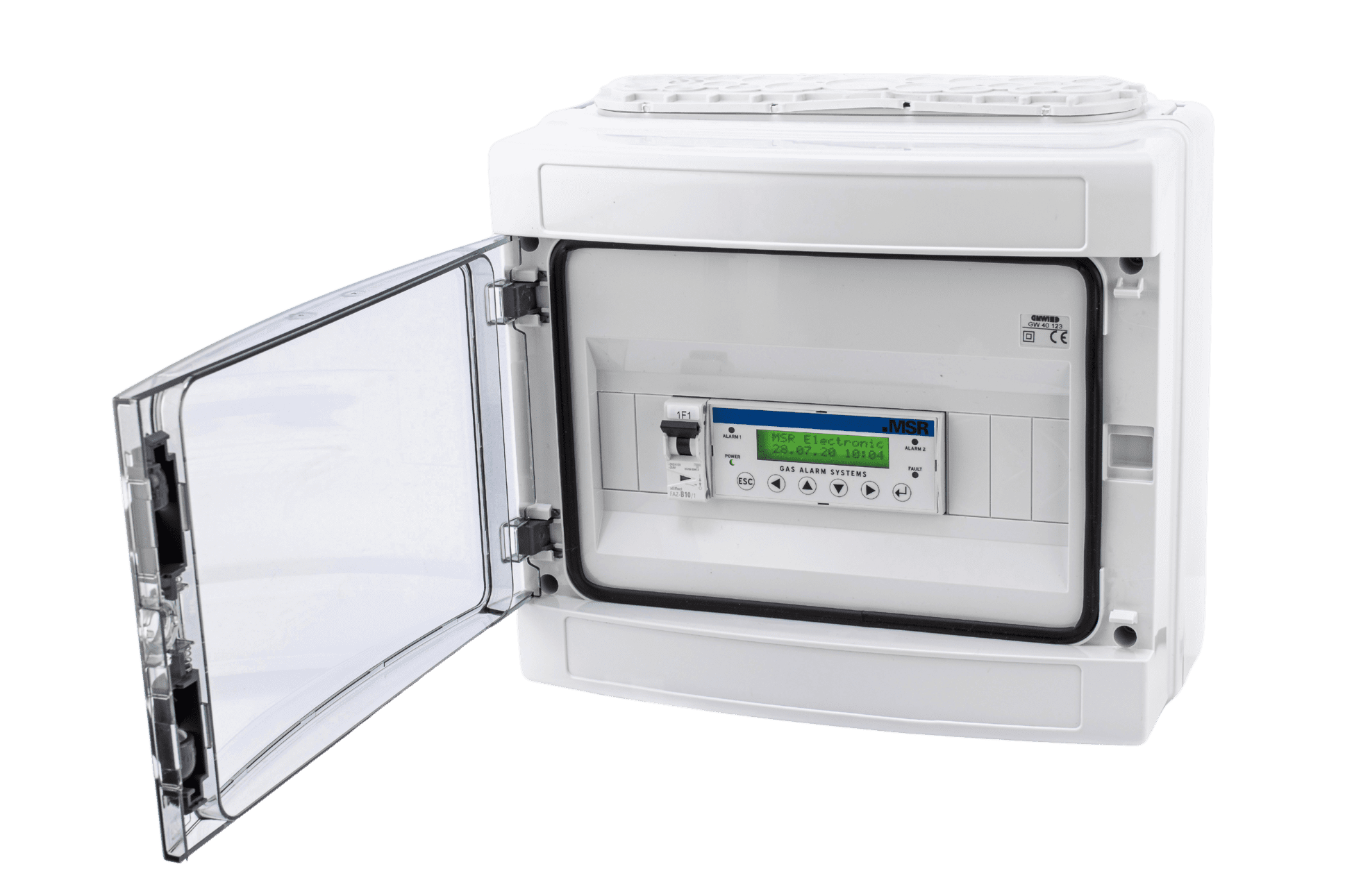

With the DGC-06 digital gas controller, MSR-Electronic GmbH has developed a ground-breaking solution that masters the challenges of gas monitoring and at the same time significantly secures production.

©MSR-Traffic GmbH

©MSR-Traffic GmbH

The DGC-06 digital gas controller: a game changer in gas monitoring.

The state-of-the-art measuring, warning and control controller system continuously monitors and analyses up to 128 gas sensors. Flexible, freely adjustable alarm thresholds recognise dangerous gas concentrations immediately. Appropriate countermeasures are then initiated.

The DGC-06 impresses with a number of remarkable features:

Reliability and availability

One of the outstanding features of the DGC-06 is its high reliability and availability. The system is equipped with self-monitoring and can optionally be connected to an uninterruptible power supply (UPS). This ensures that the system remains fully functional even in the event of power failures.

Versatile application possibilities

The DGC-06 is suitable for more than 50 different gases and can be used flexibly in various areas of gas measuring technology. This makes it an ideal solution for the various requirements in the pharmaceutical industry.

Simple operation and configuration

The operation and configuration of the DGC-06 is extremely simple. The intuitive menu navigation and the option of parameterisation via the PCE06 software enable quick and uncomplicated commissioning without the need for special programming knowledge.

Seamless integration

The controller can be seamlessly integrated into existing control systems. Thanks to various interfaces and protocols, centralised monitoring and control is possible, which further increases the efficiency of production processes.

©MSR-Traffic GmbH

©MSR-Traffic GmbH

The difference the DGC-06 makes.

By implementing the DGC-06 digital gas controller, pharmaceutical companies benefit from a significant increase in safety and efficiency. The system not only ensures the protection of employees and systems, but also optimises production processes. Unforeseen breakdowns and faults can be minimised and operating costs sustainably reduced.

The DGC-06 was developed for large systems, tunnels or even for extensive connections. Everything is possible, from complex garages to access functions that are switched by gas alarm.

The DGC-06 gas controller series can monitor and evaluate up to 128 gas sensors, including 96 digital and/or 32 analogue sensors (4-20 mA). There are 4 freely adjustable alarm thresholds per sensor.

For alarm signals, the controller system has up to 128 relays with potential-free change-over contact and up to 16 analogue outputs with 4-20 mA signal.

Further information on MSR products can be found in the current online catalog or in the webshop www.msr-24.com.