MSR-Electronic digital gas sensors monitor CO2 and lack of oxygen.

Supercritical CO2 extraction is a proven, environmentally-friendly, guaranteed chemical- and solvent-residue-free process. This process is used to generate a wide variety of extracts and raffinates.

Pressurisation and temperature adjustment increase the density of the liquid CO2 – creating a supercritical state that makes it possible to extract specific substances in different fractions. This method is particularly suitable for lipophilic substances such as fats, oils and waxes. It is also used, for example, in the production of CBD oil.

©Hopfenveredlung St. Johann GmbH (NATECO2), Germany

The company NATECO2, based in Bavaria, is an expert in the careful and solvent-free extraction of natural substances for the food, beverage, cosmetics and pharmaceutical industries, using CO2.

NATECO2 processes up to 20,000 tonnes of various raw materials per year, operates worldwide and is the largest provider of CO2 contract extraction. An in-house research and development centre as well as a certified analysis laboratory round out its comprehensive range of services.

Where is detection carried out?

The gas displaces the oxygen in the ambient air and is thus a danger to human life. Therefore, CO2 detection is urgently needed in the working areas of extraction plants.

MSR-Electronic solutions for reliable CO2 gas detection.

MSR offers reliable fixed gas warning systems that provide continuous monitoring of the ambient air for dangerous gas concentrations. This protects lives and plants. MSR also develops individual gas sensors and gas warning systems that can detect toxic or combustible gas concentrations.

NATECO2 uses the exchangeable sensor system with digitalised measurement value processing, temperature compensation and self-monitoring for continuous monitoring of the ambient air.

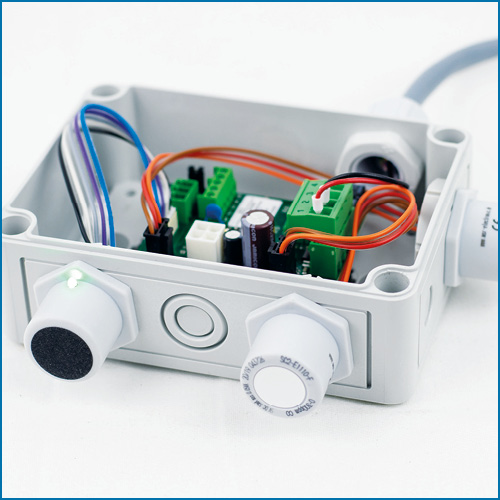

©MSR-Electronic GmbH, WSB2 Warning-and-Sensor-Board with digital gas sensors

Digital gas sensors (type SC2) are used to detect CO2. The exchangeable sensor system consists of Warning and Sensor-Board (type WSB2) and sensor head (type SC2) components.

This sensor head has an independent μController that evaluates and stores all relevant measuring values and data of the sensor element. The sensor head transfers this data to the board via the internal local bus. Up to 3 sensor heads for different gases can be connected to the WSB2. These can be mounted directly on the WSB2. The WSB2 also communicates with the DGC-06 Gas-Controller – the heart of the fixed gas warning system – via the RS-485 field bus interface.

Thanks to the X-Change Technology, calibration can be performed by simply exchanging the sensor head (type SC2). It also can be exchanged by the integrated, convenient calibration routine directly at the plant. MSR gas sensors are designed to connect to the MSR controllers and boards. The DGC-06 controller is suitable, for example, for large plants and manages up to 128 gas sensors, the Compactcontroller up to 10 gas sensors and the MSC2 controller up to 3 gas sensors.

The control centre: The DGC-06 Gas-Controller

©MSR-Electronic, Controller System DGC-06

This controller is used for monitoring and warning of toxic and combustible gases and vapours. Furthermore, it monitores Freon refrigerants in a wide range of gas measuring technology applications. A large number of freely configurable parameters and set points, individual adaptation to many applications is enabled.

The DGC-06 Gas-Controller also fulfils the functions of carbon monoxide monitoring in parking garages, tunnels and go-kart tracks and is compliant with the current EN 50545-1 standard.

Further information on MSR products can be found in the current online catalog or in the webshop www.msr-24.com.