What to keep in mind when assembling gas sensors.

Different gas characteristics and complex interactions in the environment mean that not all gases are detected at the same height. The height and positioning of a gas sensor are therefore of crucial importance for detecting dangerous gases and vapours early on.

Why are gas sensors mounted at different heights?

Gas density

Not all gases are detected at the same height, as gases concentrate at different heights due to their density. A gas may be heavier or lighter than the air. Heavy gases tend to sink downward, while lighter gases rise upward. As a result, a heavy gas that remains near the floor will not be detected in higher areas and a light gas that rises upward will not be detected near the floor.

For example, carbon monoxide in the garage is measured at almost the same density as air and at breathing height. Carbon dioxide, on the other hand, has a relative density of 1.53 and is measured near the floor. Methane has a relative density of 0.56, moves quickly to the ceiling and is measured in that area.

Gas distribution

Gas distribution in the environment is also of crucial importance. The way in which a gas is distributed in a room depends on various factors, such as ventilation, temperature and the position of the source.

The concentration of gases is thus higher near the potential source than it is near the floor or ceiling. Positioning the gas sensor correctly ensures that a hazardous gas concentration will be detected immediately, before it spreads through the room.

Reaction times and sensitivity

Different reaction times and gas sensor sensitivity are also of crucial importance. A gas sensor located near the floor will react to gas that accumulates there faster than a gas sensor near the ceiling.

©MSR-Traffic GmbH

©MSR-Traffic GmbH

What else affects the gas sensor height?

- Environmental conditions: Environmental conditions in the industry vary. By placing gas sensors at a variety of heights, differences in temperature, air current, or gas distribution, for example, are easier to detect.

- Adapting to process requirements: Some processes require gas sensors to be placed in specific locations in order to monitor and control the relevant parameters. This is particularly true of complex production environments such as beverage manufacturing and automatic processing machines. The atmospheres in these areas are often made up of inert gas, which changes the specific density of gases relative to one another. One example of this is measuring oxygen in an argon atmosphere.

- Safety standards: Placing gas sensors at different heights helps to ensure safety by monitoring potential hazards or gas leakages on different levels of a building or a plant and triggering an immediate alarm in the event of a hazard. These safety standards may be required by standards. So for example, a sensor height of 1.5-1.8 m is defined in garages for measuring carbon monoxide.

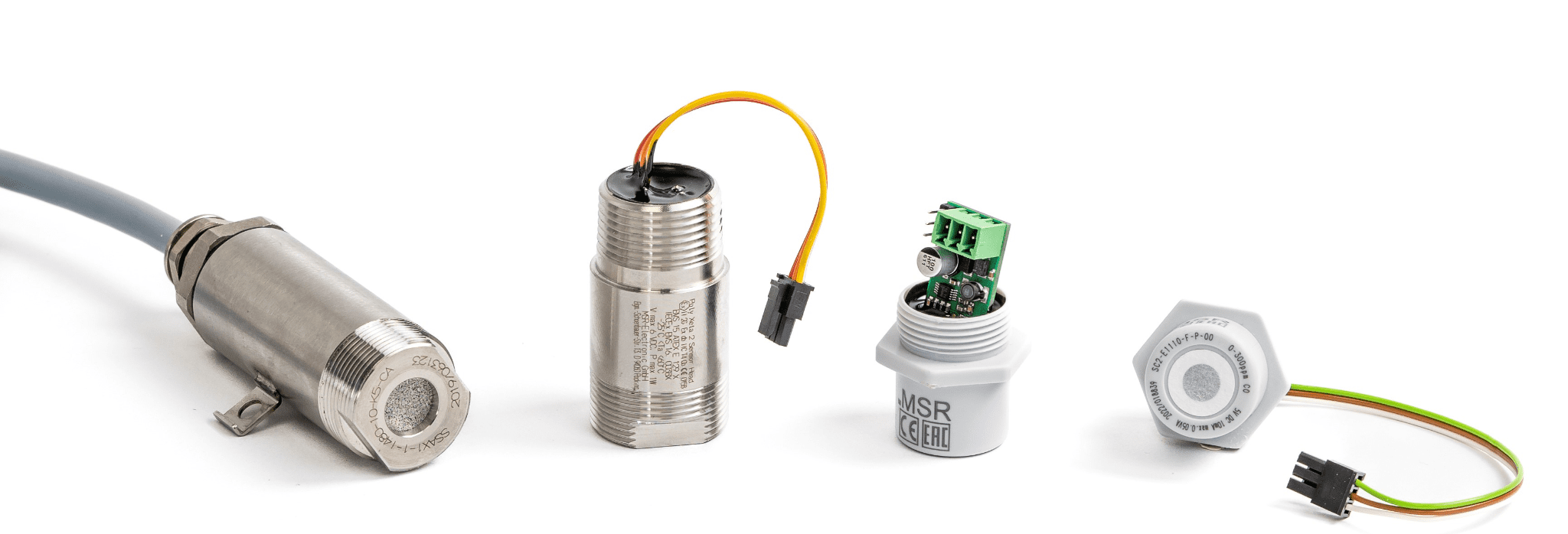

HOW are the gas sensors mounted?

The gas sensors are mounted in housing that protects them from outside influences. For comprehensive IP protection, the housing is installed with the gas sensor head pointing down. If the gas sensor is mounted at the wrong height, for example, the gas cannot be detected early. If the gas sensor is mounted mechanically incorrectly, the sensor's IP protection is not guaranteed. It must also be clarified whether there is an air current and whether the gas sensor should be mounted on the ceiling or floor.

In garages, for example, there is a static current. A sensor here can detect the gases within a radius of 7-11 m, corresponding to approx. 400 m².

WHICH type of connection does MSR-Electronic offer?

MSR-Electronic uses a 3-conductor system for analogue gas sensor connections and a 4-conductor system for bus connections. The 3-conductor connector for the 4-20 mA connection is a stable connection type for an analogue connection. Each individual gas sensor is connected to the controller by means of complex wiring.

©MSR-Traffic GmbH

©MSR-Traffic GmbH

With the bus connection, on the other hand, only one cable is placed leading from the controller to the area being monitored. The individual bus users, such as “small light bulbs”, are mounted on a string of lights. The gas sensors are addressed here and communicate digitally with the controller.

Further information on MSR products can be found in the current online catalog or in the webshop www.msr-24.com.