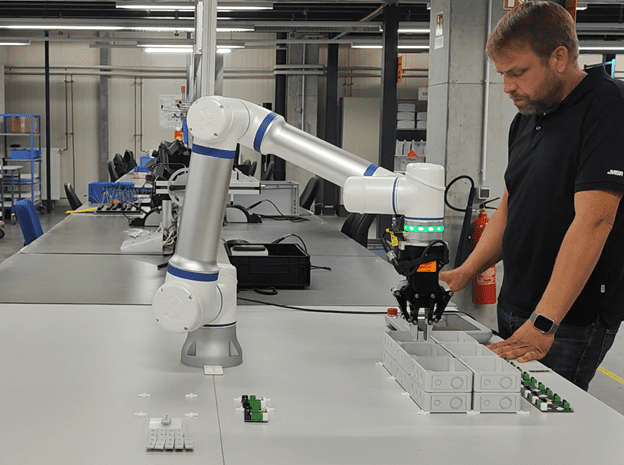

MSR-Electronic from Pocking is making a substantial contribution to Industry 4.0 and using robots for product manufacturing.

Collaborative robots are of crucial importance in industry and production. The robots make production processes safe and efficient, thus providing considerable relief for workers and production. By taking over repetitive manufacturing processes, they allow workers to devote their skills to more worthwhile tasks. Not only does this improve productivity and efficiency, but the level of quality as well.

©MSR-Traffic GmbH

©MSR-Traffic GmbH

©MSR-Traffic GmbH

©MSR-Traffic GmbH

To establish the areas of robotics and automation technology in the company, MSR-Electronic has recently started using a collaborative robot, model Elite Robots CS66, in production.

This has already succeeded in simplifying a number of steps in production. Its high user friendliness makes it optimal for tending to machines and assisting devices.

How is the robot used?

The robot is primarily used to assist workers. The robot takes over simple, repetitive tasks that, while important, take a lot of time for workers to do. Currently the priority is manufacturing series products, which the company also manufactures as stock items.

Standard products such as the PolyGard® Sensor-Board SB2 can be manufactured easily and automatically in this way. To do this, workers program the robot via a teach panel and give it production parts. Then the robot automatically manufactures the SB2.

Click here for the video.

The robot is very easy to control and program using dedicated software. The robot is currently still being tested and its potential areas of use are being determined. “In the future, it would be conceivable that the Cobot could take over preparatory work steps and the workers could perform only the more complex tasks”, says Christoph Krüger, head of the work preparation department.

Further information on MSR products can be found in the current online catalogue or in the webshop www.msr-24.com.