Reliable safety solutions are crucial for companies that use gas detectors.

MSR-Electronic, as a technological leader in gas detection technology, together with its global partner network, offers customised services for maintenance, calibration and system checks in order to ensure the optimum performance and safety of gas detectors. The company pursues a comprehensive maintenance approach that includes not only inspections and adjustments, but also preventive measures so that ensure functional safety.

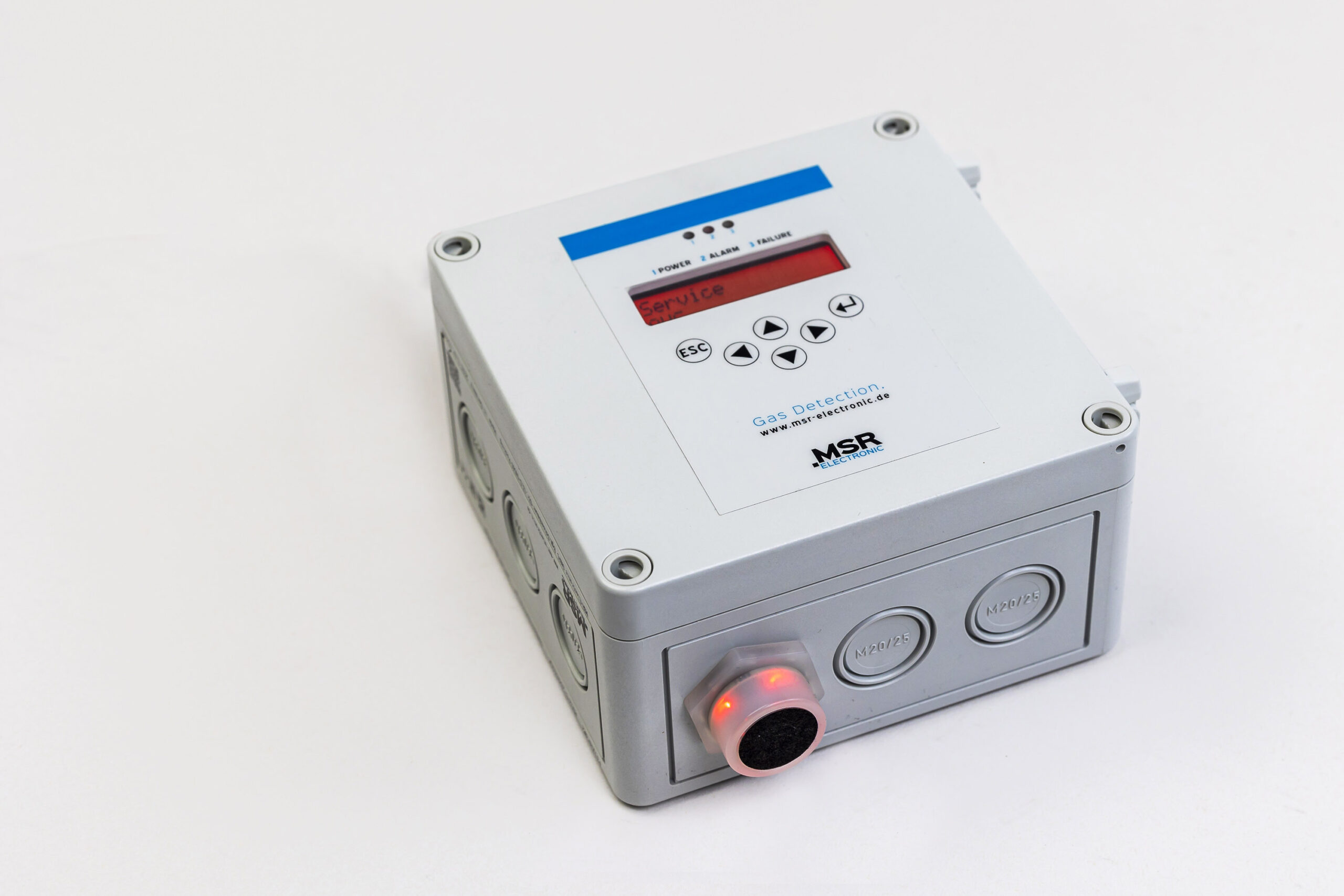

©MSR-Traffic GmbH

©MSR-Traffic GmbH

Maintenance and calibration: safety at the highest level

Regular maintenance is essential to ensure that gas detectors work according to the manufacturer's specifications. MSR-Electronic and its partner network carry out all necessary measures in accordance with the applicable technical standards to keep devices in the best possible condition. Calibration and adjustment go hand in hand.

The precise comparison between actual and target values optimises measurement accuracy and corrects deviations in real time. This is particularly essential in safety-critical areas, where exact measured values are crucial to health and safety.

Inspection and functional checks: prevention through precise control

Another important part of the service offering is the regular inspection, which includes a visual check of the devices for external damage and signs of wear. Calibration and maintenance intervals are also checked in order to recognise potential failures in good time. In addition, MSR-Electronic carries out comprehensive functional checks using both zero and Test Gases to test the sensors and measured value display. Deviations are corrected immediately and all results are documented in a test report.

©MSR-Traffic GmbH

©MSR-Traffic GmbH

System checks: Safety comprehensively tested

A system check also includes safety-related tests, which are specifically aimed at ensuring that all safety-critical components such as ventilation systems and alarms are functioning correctly. These checks are carried out by qualified specialist personnel from our partners who are trained in accordance with the strict requirements of TRBS 1203 and BetrSichV for working in potentially explosive atmospheres.

The staff are comprehensively trained in both the operation of the devices and the measuring principle and ensure that they always fulfil the highest safety standards through regular further training with external providers and in-house at MSR-Electronic.

Specialist staff and industry-specific expertise

MSR-Electronic and its partners rely on professionally qualified personnel who have undergone extensive training and have specific knowledge of gas detection technology. This includes knowledge of the handling and use of Test Gases as well as the calibration and adjustment of gas detectors. When working in potentially explosive atmospheres, additional requirements apply, which the MSR-Electronic team ensures through regular training and further education.

Recommendations for maintenance intervals and documentation

The maintenance guidelines of MSR-Electronic are generally based on the recommendations of the BG-RTI data sheets T021/T023 as well as our own long-term tests, which result in specific intervals for the individual test measures. We recommend a visual inspection every 3 months and a display test before each shift. A functional test should be carried out every six months and a system test every year. This information deviates slightly from the specifications in the data sheets and it is pointed out that standards and regulations applicable to the respective countries and applications, where applicable, must be observed. These measures will ensure that all gas detection systems remain in proper condition and that potential safety risks are minimised.

©MSR-Traffic GmbH

©MSR-Traffic GmbH

In addition, MSR-Electronic and its partners offer complete documentation of all inspections, adjustments, calibrations and functional checks carried out in order to ensure traceability and transparency. These regular inspections and written documentation are particularly important in safety-relevant industries such as the chemical, petrochemical or pharmaceutical industries, but also in the marine sector.

Solution from MSR-Electronic - Your partner for safety and efficiency in gas detection technology

Together with its trained partner network, MSR-Electronic offers comprehensive maintenance management for gas detection devices, focussing on safety and reliability in all areas of operation and applications. Through regular maintenance, calibrations and system checks as well as its comprehensive expertise, MSR-Electronic ensures that your gas detection devices are in perfect condition at all times and that potential hazards are detected at an early stage. Rely on the experience and expertise of MSR-Electronic and its partners in order to ensure the long-term safety and efficiency of your operating processes.

For more information and personalised advice on our maintenance and calibration services, please contact our international partner network or your MSR-Electronic contact person.

Weitere Details zu MSR-Electronic Produkten finden Sie im Online-Katalog oder im Webshop www.msr-24.com.