Intelligent gas warning devices from MSR-Electronic ensure a reliable gas detection in engine rooms and cargo holds of ships at an early stage

Commercial shipping poses a particular risk in the event of dangerous gas leaks, as there is no possibility of escape for the crew. It is therefore all the more important to detect and avoid hazards at an early stage.

Particularly high risks arise, among other things, in engine and crew rooms and in case of transports of hazardous materials and gas. Fuel emissions and interting systems also pose high risks. Therefore, in order to detect dangerous gas leaks and prevent fires, gas detectors from MSR-Electronic are employed here. The reliable gas warning devices not only protect equipment and systems on the ship, but in particular the lives of the crew.

©istock: 487495098, suriyasilsaksom, Cargo ship

How are the gas detectors used in the marine sector?

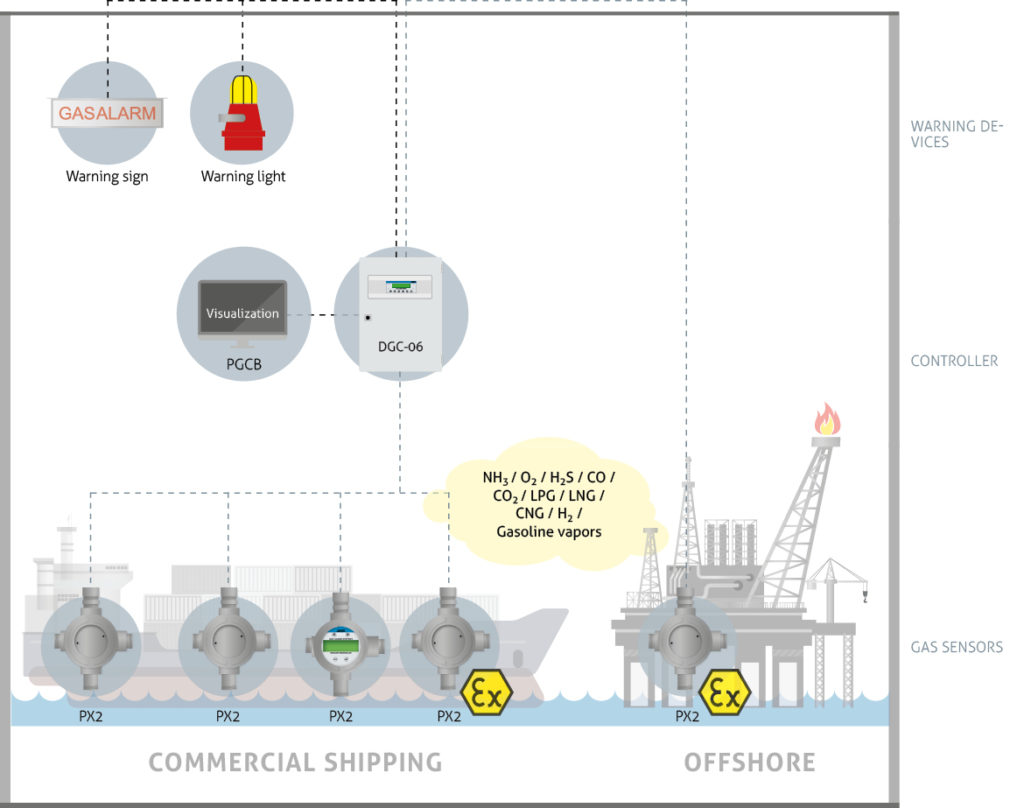

The gas detectors are used to measure combustible and toxic gases as well as oxygen. Therefore, by analysing oxygen and monitoring the gas concentration, the ambient air on board is continuously checked. In the event of increased values, an early warning is given. This prevents the release of hazardous gases into the atmosphere.

©MSR-Electronic, Gas detection navy and offshore

Furthermore, high risks also arise during inerting processes. Here, low-reaction substances are added to the tank to displace the oxygen in the tank. Thus the formation of explosive gas mixtures is avoided. It is particularly important that the maximum permissible oxygen concentration is not exceeded.

If the oxygen concentration in the inerting system is nevertheless exceeded, the crew on the ship is immediately warned and an alarm is triggered. In this way, measures can be taken at an early stage and people and equipment can be protected.

MSR-Electronic solutions for reliable gas detection in shipping

The Px2 gas detector is used for gas detection on board.

The PX2 detector with microprocessor, 4-20mA / RS485 Modbus output signal, alarm and fault signal relay monitors the ambient air for toxic and combustible gases. In addition, the gas detector also monitors the oxygen concentration and refrigerant. Optionally, the unit is also available with LC display.

©MSR-Electronic, PolyXeta®2

The calibration of gas detectors without LCD display is carried out via the calibration device STL06 or the PC software PCE06. Gas detectors with LCD display have an integrated calibration routine. This routine is started from the outside by a permanent magnet without opening the housing. In case of an alarm or failure therefore the backlight of gas detectors with LCD display changes from green to red.

Certified with ATEX, IECEx and, for some types, with the tested measuring function, the unit is optimally suited for electrical explosion protection in Zone 1 and Zone 2.

BENEFITS OF THE GAS LEAK DETECTOR

- MED Certificate and TA Certificate: Approval according to Marine Equipment Directive 2014/90/EU by DNV

- PX2-1 for zone 1 (and also suitable for zone 2): Type “Ex db” protection flame-proof enclosure

- SIL2 safety functions 4–20 mA, RS-485 and relay

- Enclosure: Additional FM and CSA certificates for Class I, Div. 1

- Continuous self-monitoring

- Microprocessor with 12-bit converter resolution

- Reverse polarity protection

- Overload protection

- Easy calibration

- Calibration service by exchanging the sensor head

- Proportional 4–20 mA output

- Serial interface to the control centre

- Alarm and fault signal relay

OPTIONAL FEATURES

- LCD display with status LEDs

- Connection of SSAX1 sensor head – not in conjunction with tested measuring function for explosion protection

- IP66 protection with SplashGuard accessories

APPLICATION OF THE GAS LEAK DETECTOR

The PolyXeta®2 PX2 detector is used on ships, shipyards and offshore platforms. Furthermore it also finds application in industrial areas like oil/gas industry, biogas plants, petrochemical industry and power plants in Ex Zone 1 or 2. The PolyXeta®2 gas detector is also suitable for commercial areas like gas transfer like e.g. gas transfer stations etc.

Due to the 4–20 mA / RS-485 Modbus output signal the gas detector is suitable for connection to the PolyGard®2 gas controller series by MSR-Electronic, as well as to any other controllers or automation devices.

Further information on MSR products can be found here in the current online catalog or in the webshop www.msr-24.com.